Designed for system integrators, OEMs, and industrial operators

Passive

Retrofit-ready

Rugged

Performance-driven

The Challenge

Traditional cryogenic dispensing systems struggle with uneven cooling distribution, excessive LN₂ boil-off, and splashing that damages equipment and creates hazardous conditions.

Localized thermal shock can crack conveyor belts and substrates. Pooling and runoff waste expensive liquid nitrogen while failing to achieve uniform process temperatures.

The Solution

Phazent's engineered approach to cryogenic dispensing leverages controlled two-phase flow dynamics and precision dispersion geometry to deliver uniform cooling coverage across the target surface.

Our passive mechanical systems eliminate electronics and moving parts in the cryogenic zone, ensuring reliable operation in dust, vibration, and moisture. The result: improved process control, reduced nitrogen consumption, and extended equipment life.

Featured Product

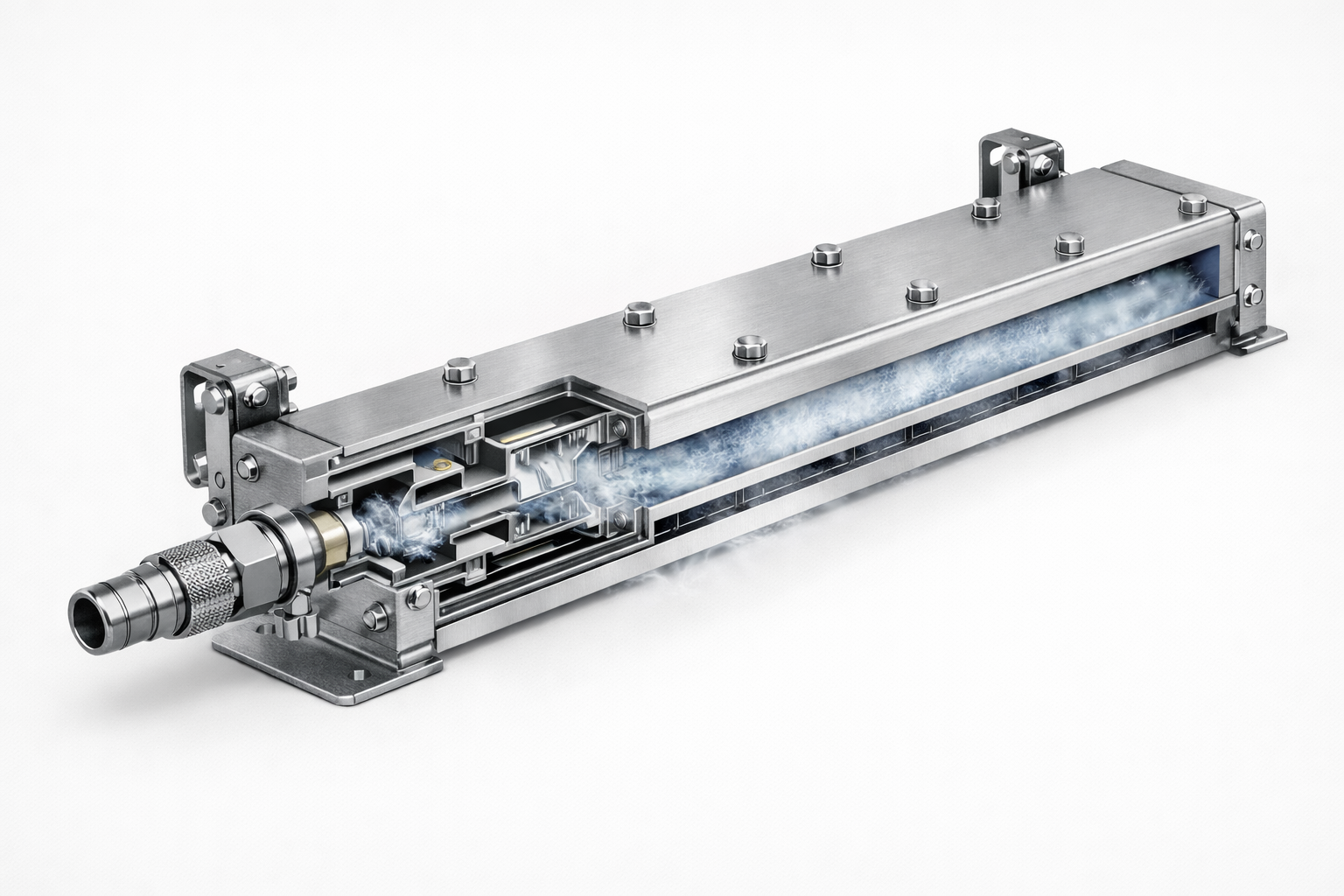

CryoCurtain™

A slotted laminar curtain LN₂ emitter producing a uniform sheet flow for superior cooling performance.

- Improves cooling uniformity across target surface

- Reduces pooling, splashing, and nitrogen waste

- Minimizes localized thermal shock and belt damage risk

- Retrofit-friendly passive design for harsh environments

- No electronics or moving parts in cryogenic zone

Applications

Engineered for harsh industrial environments requiring precise cryogenic cooling with minimal maintenance.

Concrete & Aggregate Cooling

Rapid temperature reduction for ready-mix concrete and aggregate materials in hot climates.

Conveyor Cooling

Uniform cooling across moving conveyor belts for food processing and materials handling.

Food Freezing

Controlled cryogenic freezing for IQF applications and food processing lines.

Bulk Materials Processing

Temperature control for powders, granules, and bulk solids in continuous processes.

Cryogenic Manufacturing

Precision cooling for additive manufacturing, metalworking, and materials science.

Process Cooling

General industrial cooling applications requiring uniform LN₂ distribution.

Why Phazent

Performance Engineering

Measurable improvements in cooling uniformity, nitrogen efficiency, and process control through rigorous fluid dynamics analysis.

Passive Mechanical Design

No electronics or moving parts in the cryogenic zone. Reliable operation in dust, vibration, moisture, and extreme temperatures.

Retrofit-Friendly

Designed to integrate with existing LN₂ supply systems and industrial infrastructure without major modifications.

Manufacturable Hardware

Precision-machined 316L stainless steel construction with optional ceramic coatings for extended service life.

ROI-Driven

Reduced nitrogen consumption, lower maintenance costs, and extended equipment life deliver measurable return on investment.

Frequently Asked Questions

Technical answers for engineers and procurement teams