Overview

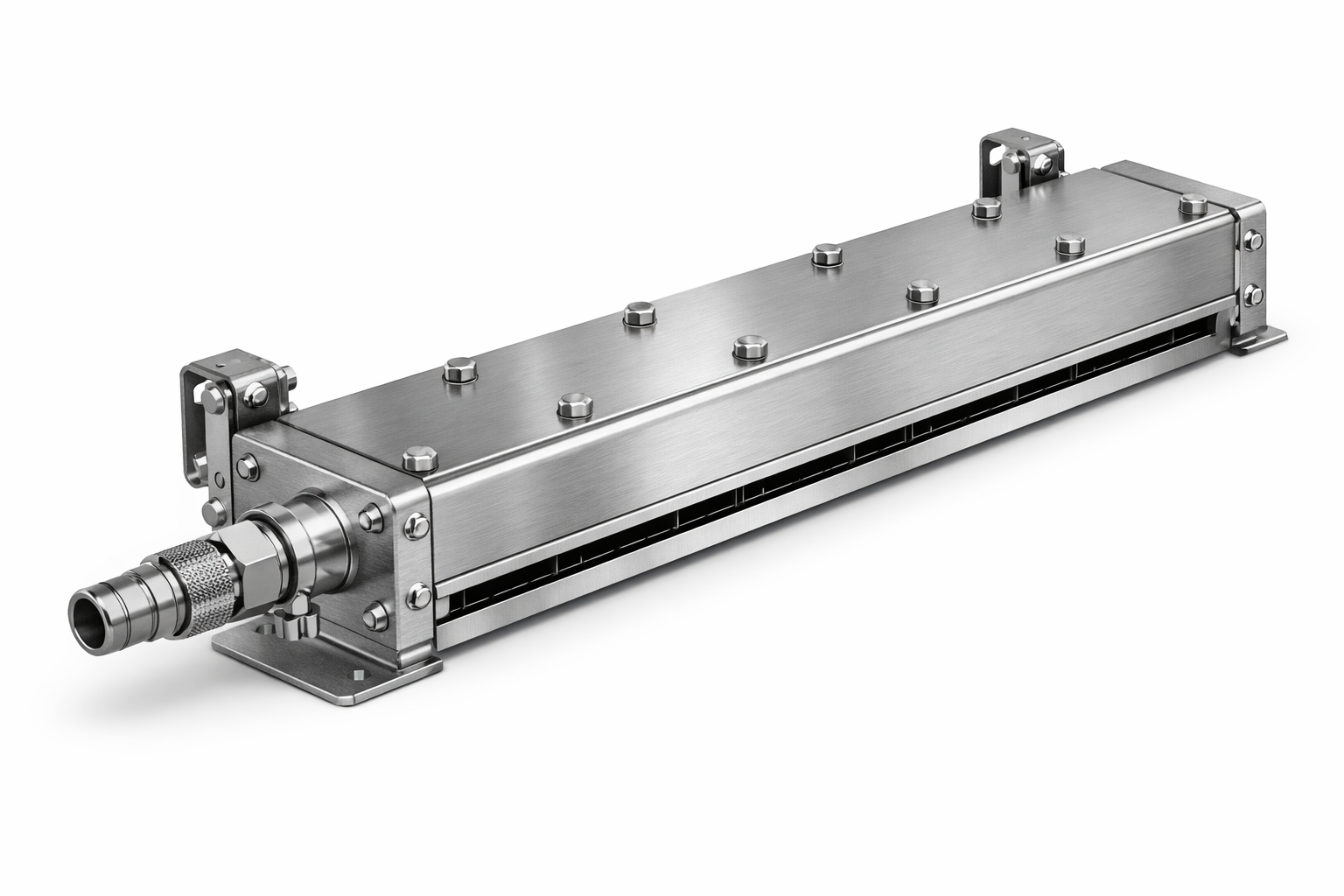

CryoCurtain™ represents a fundamental advancement in cryogenic dispensing technology. Unlike conventional nozzles that produce concentrated streams or uncontrolled spray patterns, CryoCurtain generates a uniform laminar sheet of liquid nitrogen across the entire target width.

This engineered approach to LN₂ distribution eliminates hot spots, reduces thermal shock, and maximizes cooling efficiency while minimizing nitrogen consumption. The passive mechanical design ensures reliable operation in the harshest industrial environments—no electronics, no moving parts, no maintenance headaches.

How It Works

Internal Plenum Conditioning

Liquid nitrogen enters a precision-machined internal plenum that conditions the flow and equalizes pressure across the entire width of the dispenser. This ensures uniform distribution before the LN₂ reaches the emission slot.

Laminar Slot Design

The conditioned LN₂ exits through a precision slot that produces a laminar sheet flow. The slot geometry is engineered to maintain flow stability and prevent turbulence, even at high flow rates.

Controlled Two-Phase Flow

As the LN₂ sheet contacts the target surface, controlled vaporization occurs across the entire coverage area. This two-phase flow dynamic maximizes heat transfer while minimizing splashing and boil-off waste.

Key Benefits

Improved Cooling Uniformity

Laminar sheet flow eliminates hot spots and ensures consistent temperature across the entire target surface.

Reduced LN₂ Waste

Efficient distribution and controlled vaporization minimize boil-off and runoff, reducing nitrogen consumption.

Minimized Thermal Shock

Uniform coverage prevents localized temperature extremes that can crack conveyor belts and damage substrates.

Equipment Protection

Reduced splashing and pooling protect surrounding equipment from cryogenic damage and ice buildup.

Passive Mechanical Design

No electronics or moving parts in cryogenic zone. Reliable operation in dust, vibration, and moisture.

Retrofit-Friendly

Integrates with existing LN₂ supply systems using standard industrial fittings. No major modifications required.

Typical Applications

Technical Specifications

| Parameter | Specification |

|---|---|

| Construction Material | 316L stainless steel |

| Optional Coating | Ceramic-coated edge insert for extended wear life |

| Inlet Connection | Standard industrial cryogenic fittings |

| Available Widths | Multiple configurations (consult engineering) |

| Flow Range | Application-dependent (consult engineering) |

| Operating Environment | Harsh industrial: dust, vibration, moisture, temperature extremes |

| Mounting | Precision-drilled mounting holes for rigid installation |

| Maintenance | Minimal - periodic inspection and cleaning |

Note: Specifications are application-dependent. Contact our engineering team for detailed sizing and configuration recommendations.

Integration & Retrofit

CryoCurtain is designed for straightforward integration with existing industrial LN₂ supply infrastructure. The system requires no specialized control electronics or proprietary interfaces—just a regulated liquid nitrogen supply at appropriate pressure and flow rate.

Mounting provisions accommodate standard industrial hardware, and the compact form factor fits into tight spaces common in retrofit applications. Our engineering team provides application support to ensure optimal positioning, flow rates, and integration with your existing process control systems.

Installation Considerations

- •Adequate clearance for LN₂ vapor expansion and ventilation

- •Rigid mounting to minimize vibration and maintain alignment

- •Appropriate supply line sizing and insulation

- •Safety interlocks and emergency shutoff provisions

- •Personnel training on cryogenic safety procedures